- Manager:

- Mr.Chen

- Mobile:

- 0086-13776866887

- Email:

- sales@bestarsensor.com

- Company Name:

- BeStar Sensortech Co., Ltd.

- Add:

- No. 39, Xinggang Road,Zhonglou District, Changzhou, Jiangsu, P.R. China

Perceiving the world,creating intelligent life

The development of ceramics from vases, dishes and other utensils to the current functional ceramics mainly lies in the discovery of the microscopic polarization characteristics of functional ceramic crystals. Functional ceramics are dielectric materials with the main characteristics of storage, detection, coupling and conversion of electrical, magnetic, acoustic, optical, thermal and mechanical information, mainly including piezoelectric, dielectric, pyroelectric and magnetic functions. New ceramic materials, of which piezoelectric ceramics are one of the mainstream materials in the field of functional ceramics.

What is Piezoelectric Ceramics

Piezoelectric ceramics refer to polycrystals formed by mixing oxides (zirconia, lead oxide, titanium oxide, etc.) at high temperature and after solid-phase reaction, and ferroelectric ceramics with piezoelectric effect through DC high voltage polarization treatment It is a functional ceramic material that can convert mechanical energy and electrical energy into each other. Among them, lead zirconate titanate ceramics, referred to as PZT ceramics, is a binary solid solution, which exhibits an ABO3 type perovskite structure, and is a widely used piezoelectric material.

What is Piezoelectric Effect

Piezoelectric ceramics are actually information-functional ceramic materials that use the piezoelectric effect to convert mechanical energy and electrical energy into each other. Piezoelectric ceramics work like a spring that converts kinetic and potential energy into each other, and deforms when energized.

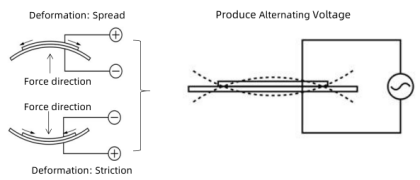

When physical pressure is applied to the piezoelectric material, the electric dipole moment in the material body will be shortened due to compression. At this time, the piezoelectric material will generate an equal amount of positive and negative charges on the opposite surfaces of the material in order to resist this change to maintain undisturbed. This phenomenon of electric polarization due to deformation is called "positive piezoelectric effect". The positive piezoelectric effect is essentially the process of converting mechanical energy into electrical energy.

▲Positive Piezoelectric Effect - Conversion of Mechanical Energy into Electricity

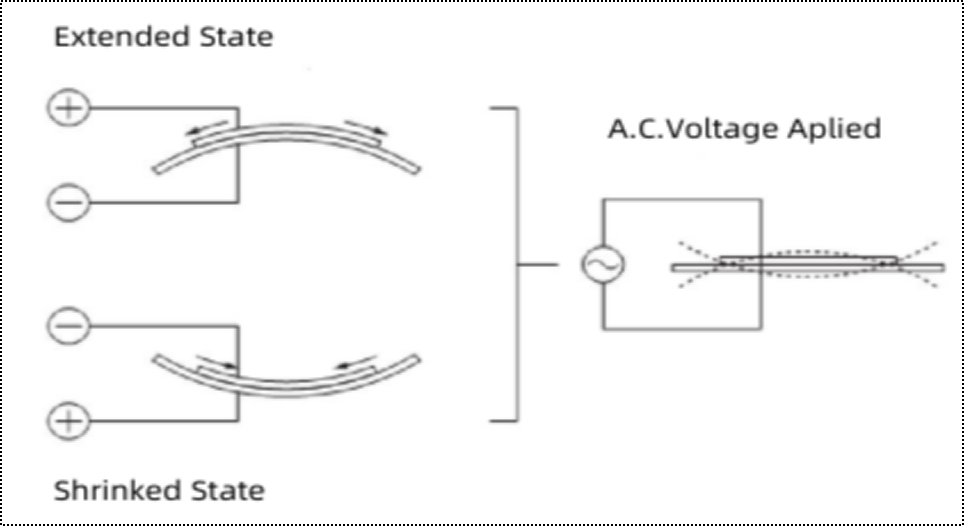

▲Inverse Piezoelectric Effect - Conversion of electrical energy into mechanical energy

The leader in the field of piezoelectric ceramics-wave speed sensor has always focused on the independent research and development of piezoelectric ceramics, constantly improving technological innovation, and continuously expanding product lines and application fields.

Multilayer Piezo Ceramic In-Ear Headphone Treble Compensation

The BPR10H0.3-5 multilayer piezoelectric ceramic series is specially used as a high-frequency compensation unit for earphones. The multilayer piezoelectric ceramic sheet has a simple structure and a thinner volume, so that it can be used in in-ear headphones. By combining with the moving coil speaker, it makes up for the lack of high frequency of the speaker and makes the sound more layered.

▲BPR10H0.3-5

▲BPR10H0.3-5

Piezoelectric haptic feedback × smartphone

A button replacement solution that detects context-sensitive swipes, taps, and clicks, while providing rich haptic feedback to allow interaction "0" distance. Using piezoelectric haptic feedback to provide timely and useful information through haptic experience, to upgrade the experience of haptic users, especially for people with visual or hearing impairments, haptic feedback can be used as the main feedback mechanism, allowing them to experience life and Information can be received faster and more timely at work.

BPH-5509S-8.0MF-HF, small and light in size, about 0.5mm in thickness, low-voltage drive, low power consumption, weak pressure sensitivity, and super vibration sense, suitable for feedback application scenarios.

![]()

▲BPH-5509S-8.0MF-HF

BPH-6206S-2.0MF-HF components are driven by medium and low voltage, with high reliability, moderate pressure sensitivity and strong vibration, suitable for tactile and feedback application scenarios.

![]()

▲BPH-6206S-2.0MF-HF

The tactile feedback actuator series of the wave speed sensor is composed of piezoelectric ceramics and a substrate. The total thickness is less than 1mm. The ultra-thin design saves the space of the touch module and meets the requirements of small package size; and the low power consumption is suitable for power consumption limited. Mobile devices can effectively save power consumption; acceleration, force and response time can provide more accurate and fast haptic feedback, because the amplitude and frequency can be freely changed by pulse control, so it can cope with various forms of vibration. Products can be applied to consumer electronics, automotive electronics, home appliances and games.

(1)-20220311053801599.png)

(1)-20220311053826276.png)

More and more devices are now equipped with haptic feedback devices, which take the user experience of game consoles, touch screen devices and mobile electronics to a whole new level.

Due to the positive and inverse piezoelectric effect, piezoelectric ceramic materials have been widely used in piezoelectric sensors, drivers, transducers and filters. Applications cover aerospace, military, information electronics, industrial machinery, medical, automotive and many other fields. Piezoelectric ceramics have the characteristics of high performance, low cost, and easy processing and preparation, and are currently the most important driving materials for piezoelectric drivers.